What is flash???

A flash is a device used in photography producing a flash of artificial light (typically 1/1000 to 1/200 of a second) at a color temperature of about 5500 K to help illuminate a scene.

A major purpose of a flash is to illuminate a dark scene. Other uses are capturing quickly moving objects or changing the quality of light. Flash refers either to the flash of light itself or to the electronic flash unit discharging the light. Most current flash units are electronic, having evolved from single-use flashbulbs and flammable powders. Modern cameras often activate flash units automatically.

Flash units are commonly built directly into a camera. Some cameras allow separate flash units to be mounted via a standardized "accessory mount" bracket (a hot shoe).

In professional studio equipment, flashes may be large, standalone units, or studio strobes, powered by special battery packs or connected to mains power. They are either synchronized with the camera using a flash synchronization cable or radio signal, or are light-triggered, meaning that only one flash unit needs to be synchronized with the camera, and in turn triggers the other units, called slaves.

Comparison of xenon flash and high current LEDs for photo flash in camera phones:::

The quality of camera phones is continually improving – more megapixels, better lenses, improved image-processing software, anti hand-shake features. The one area that has been lagging behind is the power and energy of the flash for taking pictures in low light. It is often in low light environments where people want to take photos to record the occasion, such as in restaurants, bars or nightclubs. Many cell phones have compromised by providing a low-current LED photo light or flash, which provides insufficient light energy for an acceptable photo in low light .

Now, two solutions are emerging to provide a good photo flash in low ambient light:

− high current LEDs supported by a super-capacitor

− and xenon

This article will explore the limitations of existing LED flash implementations without a super-capacitor, and go on to compare LED flash with super-capacitor and xenon flash solutions. The comparison will be across multiple dimensions:

− light power and energy

− shutter requirements

− ease of circuit implementation

− safety

− size

Light Power vs Light Energy

The light power of a flash determines how bright it appears. Naturally, this is what draws most people’s attention. However, what is important to a pixel in a camera sensor is the total amount of light it receives while it is capturing data. This is the light energy. For a flash pulse, this is the area under the curve of light power over time. If the light power is constant during the flash pulse, as is the case for LED flash, then the light energy is light power (lux) x the flash pulse duration (secs), and the unit is lux.sec.

− Xenon flash has fantastic light power, up to several hundred thousand lux, but a very short pulse duration, typically 50 – 100μsec.

− An LED Flash, with the support of a supercapacitor, can now generate upwards of several 100 lux with a flash pulse of up to ~100msecs.

This means the xenon needs to have 1000 to 2000 times the power of the LED Flash to deliver the same light energy. A major restriction on the light energy delivered by a xenon pulse is the size of the electrolytic 330V storage capacitor.

In this article we show the results of light power over time for:

− Three xenon camera phones, with varying size storage capacitors, the largest of which has an external xenon flash accessory

− Existing low-power LED flash

− A supercapacitor-based high-current LED Flash solution.

Integration of the area under the curves gives light energy available to fill pixels in the camera sensor and enables the relative merits of the two solutions to be objectively compared.

Limitations of LED Flash currently used in camera phones

The standard Flash driver is a boost converter in current control mode. There are many demands on cell phone batteries, so designers are loath to allow more than 800 - 1000mA to be drawn from the battery for LED Flash. Assume the battery voltage is 3.6V, the LED Forward voltage = 4.2V and the boost converter efficiency is 85%. Then, for 800mA battery current, the LED current = 0.8 x 3.6/4.2 x 0.85 = 580mA and LED Power = 2.4W. At this current, a typical high-current LED will only provide 7 – 8 lux at 2m distance from the scene1. If the camera sensor frame rate is 7.5 frames/sec, then the light energy per pixel = 7.5lux x 0.133s = 1 lux.sec. Figs 8 & 9 show that the light energy for a Nokia 73 with an image exposure time of 90msecs using a low current LED at 1W is only 1.7 lux.secs at 1m from the subject and 0.4 lux.secs at 2m. Most LED Flash phones today drive LED Flash @ 1W – 2W and provide < 4 lux.secs at 1m and < 1 lux.secs at 2m distance from the subject. Examples are the Nokia 6680, N70 and N73 which all drive their LED at 1W, and the SonyEricsson K750 which drives a pair of LEDs at ~2W total.

A good picture ideally requires 10 – 15 lux.secs of light energy. Until the advent of supercapacitors, a xenon flash tube was the only practical means of generating reasonable light energy, but this poses some problems for camera phones.

Xenon Flash

In a xenon flash, an electrolytic capacitor is pre-charged to 330V. This is then discharged across a tube filled with xenon gas to produce an intensely bright flash (up to several hundred 1000 lux at 1m) of very short duration (typically < 100μsec). A trigger circuit operating in the range of 4000 – 8000V is required to precipitate the gas discharge. The high energy stored at 330V is a safety concern, special care is required to prevent the high voltage trigger circuit from arcing to other circuits, and the electrolytic capacitor is bulky and difficult to fit in thin form factor camera phones.

Supercapacitor-based LED Flash::

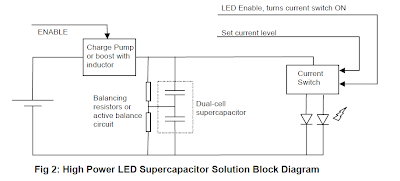

Using a supercapacitor to support LED Flash allows the battery to supply only the charge current to the supercapacitor while the supercapacitor provides all the LED current during the flash pulse. Supercapacitor-based LED flash drivers were recently detailed in Power Management Design Line,

The current switch is shown on the high side, but can also be placed on the low side of the LEDs.

The current level can be set to either fixed levels (say Torch and Flash), or the current level in flash mode can be set based on the ambient light to achieve optimum exposure for the picture. The supercapacitor has sufficiently high energy (high C) and sufficient power (low ESR) to supply the

LED current for the flash pulse with little or no contribution from the battery.

The battery charges the supercapacitor between flash photos. For example, if a 0.5F supercapacitor discharges 1V during the flash pulse, then it only requires 250mA charging current to recharge it in 2 secs to be ready for the next photo. Fig 3 shows flash current and battery current for a flash pulse driving 4 x Luxeon PWF1 LEDs at 1A each.

Note that the battery current is limited to 300mA and the supercapacitor provides all the LED current during the flash pulse.

Some major differences between the LED and Xenon flash are shown below:::-

A flash is a device used in photography producing a flash of artificial light (typically 1/1000 to 1/200 of a second) at a color temperature of about 5500 K to help illuminate a scene.

A major purpose of a flash is to illuminate a dark scene. Other uses are capturing quickly moving objects or changing the quality of light. Flash refers either to the flash of light itself or to the electronic flash unit discharging the light. Most current flash units are electronic, having evolved from single-use flashbulbs and flammable powders. Modern cameras often activate flash units automatically.

Flash units are commonly built directly into a camera. Some cameras allow separate flash units to be mounted via a standardized "accessory mount" bracket (a hot shoe).

In professional studio equipment, flashes may be large, standalone units, or studio strobes, powered by special battery packs or connected to mains power. They are either synchronized with the camera using a flash synchronization cable or radio signal, or are light-triggered, meaning that only one flash unit needs to be synchronized with the camera, and in turn triggers the other units, called slaves.

Comparison of xenon flash and high current LEDs for photo flash in camera phones:::

The quality of camera phones is continually improving – more megapixels, better lenses, improved image-processing software, anti hand-shake features. The one area that has been lagging behind is the power and energy of the flash for taking pictures in low light. It is often in low light environments where people want to take photos to record the occasion, such as in restaurants, bars or nightclubs. Many cell phones have compromised by providing a low-current LED photo light or flash, which provides insufficient light energy for an acceptable photo in low light .

Now, two solutions are emerging to provide a good photo flash in low ambient light:

− high current LEDs supported by a super-capacitor

− and xenon

This article will explore the limitations of existing LED flash implementations without a super-capacitor, and go on to compare LED flash with super-capacitor and xenon flash solutions. The comparison will be across multiple dimensions:

− light power and energy

− shutter requirements

− ease of circuit implementation

− safety

− size

Light Power vs Light Energy

The light power of a flash determines how bright it appears. Naturally, this is what draws most people’s attention. However, what is important to a pixel in a camera sensor is the total amount of light it receives while it is capturing data. This is the light energy. For a flash pulse, this is the area under the curve of light power over time. If the light power is constant during the flash pulse, as is the case for LED flash, then the light energy is light power (lux) x the flash pulse duration (secs), and the unit is lux.sec.

− Xenon flash has fantastic light power, up to several hundred thousand lux, but a very short pulse duration, typically 50 – 100μsec.

− An LED Flash, with the support of a supercapacitor, can now generate upwards of several 100 lux with a flash pulse of up to ~100msecs.

This means the xenon needs to have 1000 to 2000 times the power of the LED Flash to deliver the same light energy. A major restriction on the light energy delivered by a xenon pulse is the size of the electrolytic 330V storage capacitor.

In this article we show the results of light power over time for:

− Three xenon camera phones, with varying size storage capacitors, the largest of which has an external xenon flash accessory

− Existing low-power LED flash

− A supercapacitor-based high-current LED Flash solution.

Integration of the area under the curves gives light energy available to fill pixels in the camera sensor and enables the relative merits of the two solutions to be objectively compared.

Limitations of LED Flash currently used in camera phones

The standard Flash driver is a boost converter in current control mode. There are many demands on cell phone batteries, so designers are loath to allow more than 800 - 1000mA to be drawn from the battery for LED Flash. Assume the battery voltage is 3.6V, the LED Forward voltage = 4.2V and the boost converter efficiency is 85%. Then, for 800mA battery current, the LED current = 0.8 x 3.6/4.2 x 0.85 = 580mA and LED Power = 2.4W. At this current, a typical high-current LED will only provide 7 – 8 lux at 2m distance from the scene1. If the camera sensor frame rate is 7.5 frames/sec, then the light energy per pixel = 7.5lux x 0.133s = 1 lux.sec. Figs 8 & 9 show that the light energy for a Nokia 73 with an image exposure time of 90msecs using a low current LED at 1W is only 1.7 lux.secs at 1m from the subject and 0.4 lux.secs at 2m. Most LED Flash phones today drive LED Flash @ 1W – 2W and provide < 4 lux.secs at 1m and < 1 lux.secs at 2m distance from the subject. Examples are the Nokia 6680, N70 and N73 which all drive their LED at 1W, and the SonyEricsson K750 which drives a pair of LEDs at ~2W total.

A good picture ideally requires 10 – 15 lux.secs of light energy. Until the advent of supercapacitors, a xenon flash tube was the only practical means of generating reasonable light energy, but this poses some problems for camera phones.

Xenon Flash

In a xenon flash, an electrolytic capacitor is pre-charged to 330V. This is then discharged across a tube filled with xenon gas to produce an intensely bright flash (up to several hundred 1000 lux at 1m) of very short duration (typically < 100μsec). A trigger circuit operating in the range of 4000 – 8000V is required to precipitate the gas discharge. The high energy stored at 330V is a safety concern, special care is required to prevent the high voltage trigger circuit from arcing to other circuits, and the electrolytic capacitor is bulky and difficult to fit in thin form factor camera phones.

Supercapacitor-based LED Flash::

Using a supercapacitor to support LED Flash allows the battery to supply only the charge current to the supercapacitor while the supercapacitor provides all the LED current during the flash pulse. Supercapacitor-based LED flash drivers were recently detailed in Power Management Design Line,

The current switch is shown on the high side, but can also be placed on the low side of the LEDs.

The current level can be set to either fixed levels (say Torch and Flash), or the current level in flash mode can be set based on the ambient light to achieve optimum exposure for the picture. The supercapacitor has sufficiently high energy (high C) and sufficient power (low ESR) to supply the

LED current for the flash pulse with little or no contribution from the battery.

The battery charges the supercapacitor between flash photos. For example, if a 0.5F supercapacitor discharges 1V during the flash pulse, then it only requires 250mA charging current to recharge it in 2 secs to be ready for the next photo. Fig 3 shows flash current and battery current for a flash pulse driving 4 x Luxeon PWF1 LEDs at 1A each.

Note that the battery current is limited to 300mA and the supercapacitor provides all the LED current during the flash pulse.

Some major differences between the LED and Xenon flash are shown below:::-